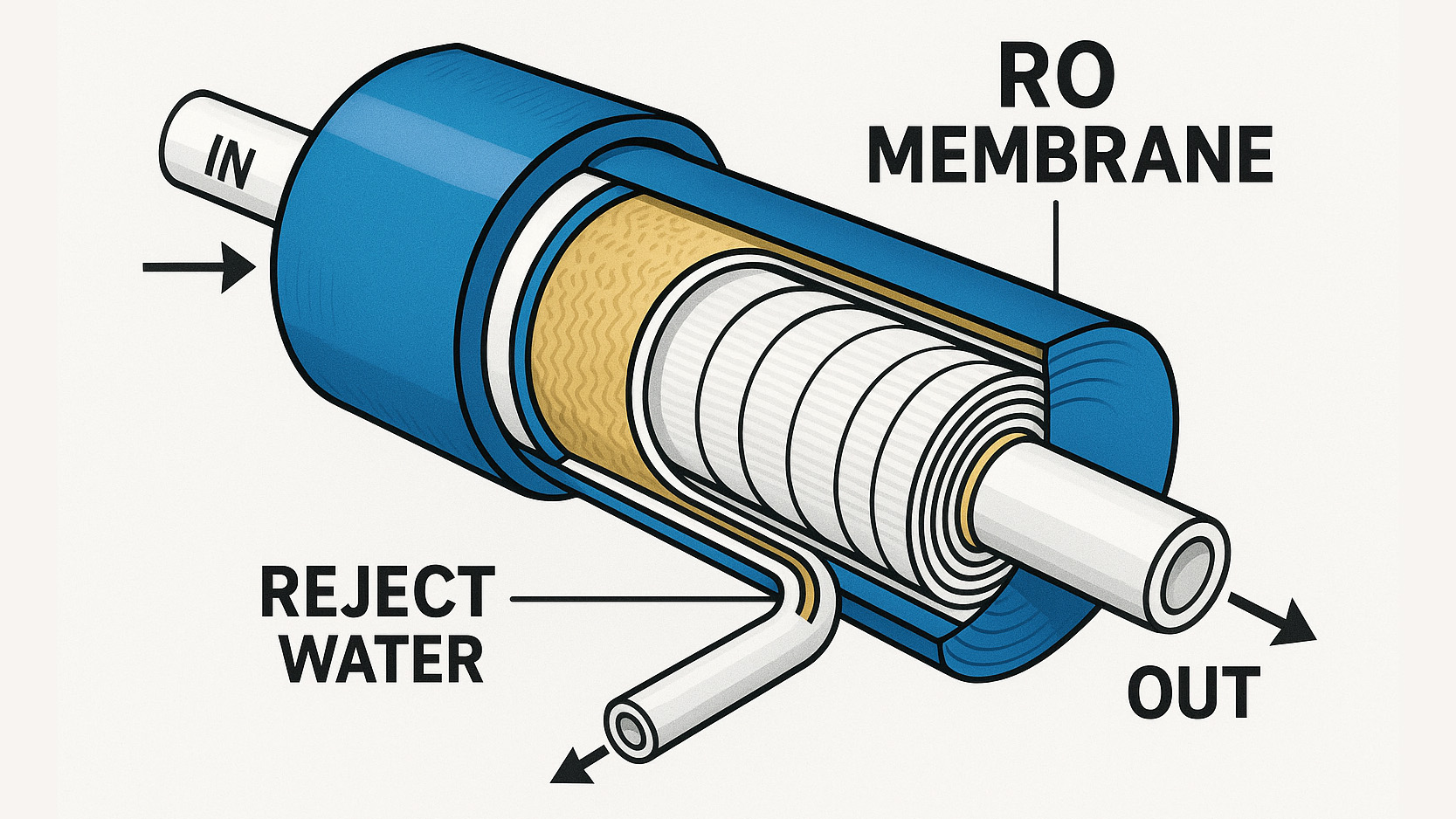

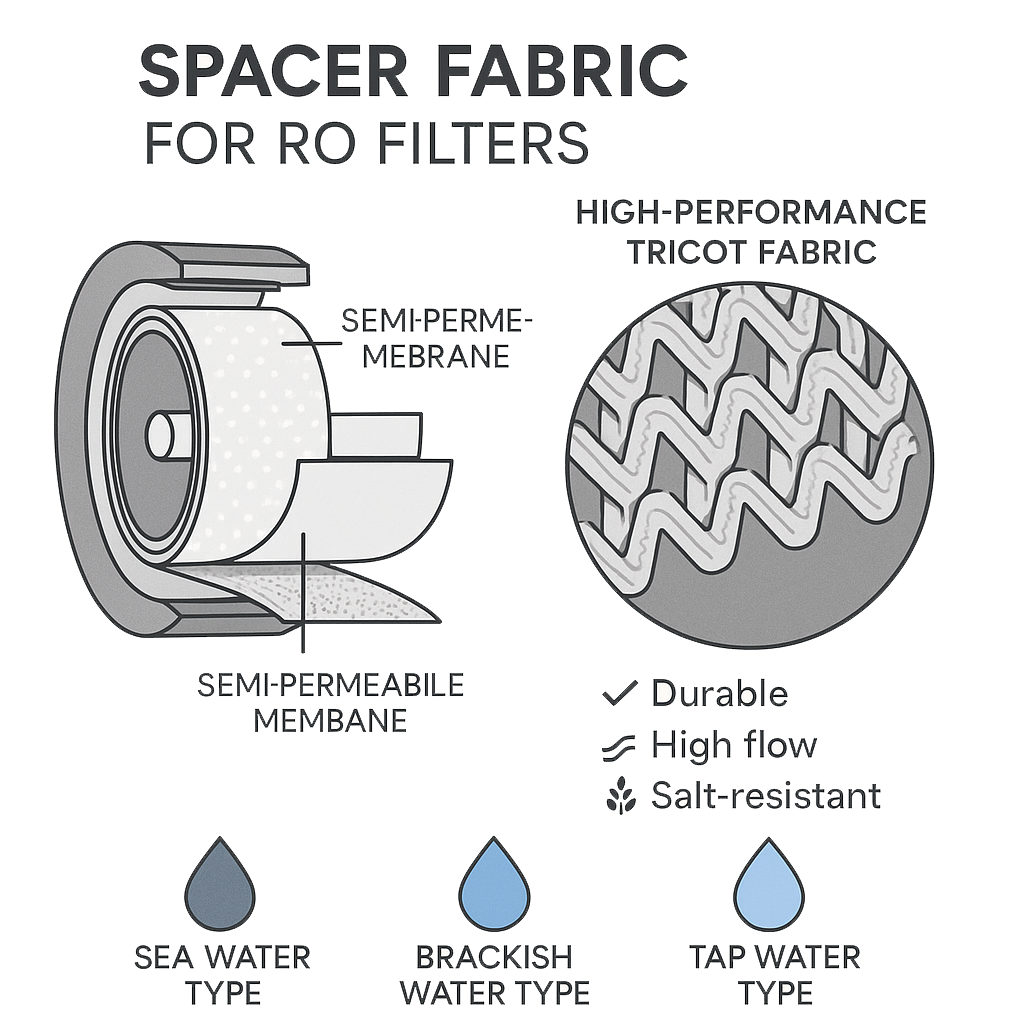

Spacer Tricot Fabrics for Reverse Osmosis (RO) Membrane Water Filters

We specialize in manufacturing high-performance spacer tricot fabrics designed for use inside reverse osmosis (RO) membrane water filtration systems.

Our fabrics are suitable for a wide range of applications, including seawater desalination, municipal drinking water purification, and industrial wastewater treatment. Produced using advanced Karl Mayer warp knitting machines from Germany, our spacer fabrics ensure consistent quality and dimensional stability. Unlike conventional methods that use epoxy-based binders—many of which contain hazardous substances such as Bisphenol A (BPA)—our fabrics are thermally bonded.

This eco-friendly process eliminates the need for chemical binders, resulting in a safer, more sustainable product.

The thermal bonding technique creates well-defined and uniform channels for water flow, offering superior permeability and flow efficiency compared to epoxy-bonded fabrics.

This enhances filtration performance, reduces pressure drop, and improves energy efficiency across a range of filtration systems.

Our spacer tricot fabrics can be customized to meet the specific requirements of different RO systems, and we uphold strict quality control standards throughout the production process.

Key Benefits:

BPA-free, epoxy-free production

Superior channel formation for optimal water flow

Chemical and temperature resistance

Suitable for seawater, drinking water, and wastewater filtration

Manufactured with state-of-the-art German knitting technology

Partner with us for innovative, eco-conscious spacer fabric solutions tailored for the most demanding water treatment applications.

High-Performance Tricot Fabric for Reverse Osmosis Water Filters

Our advanced tricot fabric is engineered specifically for reverse osmosis (RO) membrane filters.

Utilizing cutting-edge thermoplastic bicomponent fibers, this fabric offers exceptional durability, efficiency, and safety, eliminating the need for harmful chemical treatments.

1. Innovative Thermoplastic Bicomponent Fiber

Crafted from a combination of high and low melting point resins, our fabric employs a core-sheath structure.

This design ensures the necessary rigidity without the use of epoxy resins, which are known to release harmful substances like amines and bisphenol A.

By avoiding these chemicals, we provide a safer and more environmentally friendly solution.

2. Superior Mechanical Strength

The unique composition of our tricot fabric delivers excellent surface hardness and bending strength.

This robustness ensures the fabric maintains its structure under the high-pressure conditions typical of RO systems, leading to enhanced filtration performance and longevity.

3. Enhanced Filtration Efficiency

Our fabric’s design promotes optimal water flow and filtration efficiency.

The precise balance of fiber fineness and structural integrity minimizes flow resistance and maximizes permeate output, ensuring consistent and reliable performance

4. Eco-Friendly Manufacturing Process

By utilizing heat-treated bicomponent fibers, our manufacturing process eliminates the need for chemical impregnation.

This approach not only reduces environmental impact but also ensures that no harmful substances leach into the filtered water, making it safe for consumption.

Applications

Our tricot fabric is ideal for various RO filtration applications, including:

Industrial Water Treatment: Ensures efficient removal of contaminants in large-scale operations.

Residential Water Purification: Provides safe and clean drinking water for households.

Desalination Plants: Facilitates the conversion of seawater into potable water.

Food and Beverage Industry: Maintains high hygiene standards in processing and production.

Why Choose Our Tricot Fabric ?

Chemical-Free:

No use of epoxy resins, ensuring safer water filtration.

Durable:

Maintains structural integrity under high-pressure conditions.

Efficient:

Optimized design for maximum filtration performance.

Eco-Friendly:

Manufactured without harmful chemicals, reducing environmental impact.

Menu

Contact

- 1690 Roberts Blvd., Suite 107B Kennesaw, GA 30144 USA

- 678 236 0800

- 678 977 0788

- mkim@gepcoinc.com

- mikegepco@gmail.com