Permeate spacer fabric for Reverse osmosis filter

1. Tricot Spacer

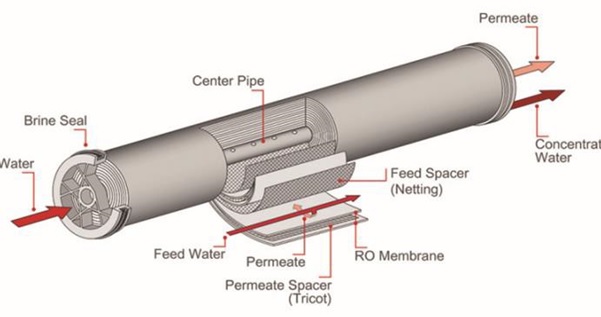

Permeate spacer/Channel Spacer is also known as a "permeate water carrier", or "mesh spacer". In the construction of a membrane element, the product channel spacer is placed between two layers of the flat sheet membrane. This spacer is made using a knit fabric called "tricot", and is used to prevent the RO membrane from closing-off on itself under the high pressure of operation. Permeate water will flow in a spiral path across the product channel spacer into the product collection tube.

2. Material

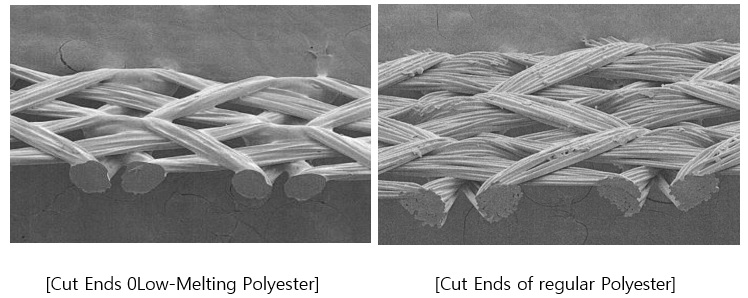

LM Filament is covered with the low-melting PET, which melts at a lower temperature (under 200 Celcius) than the regular PET. It can improve the existing health risks of epoxy-coated permeate spacer, and maintain the similar stiffness.

3. Products