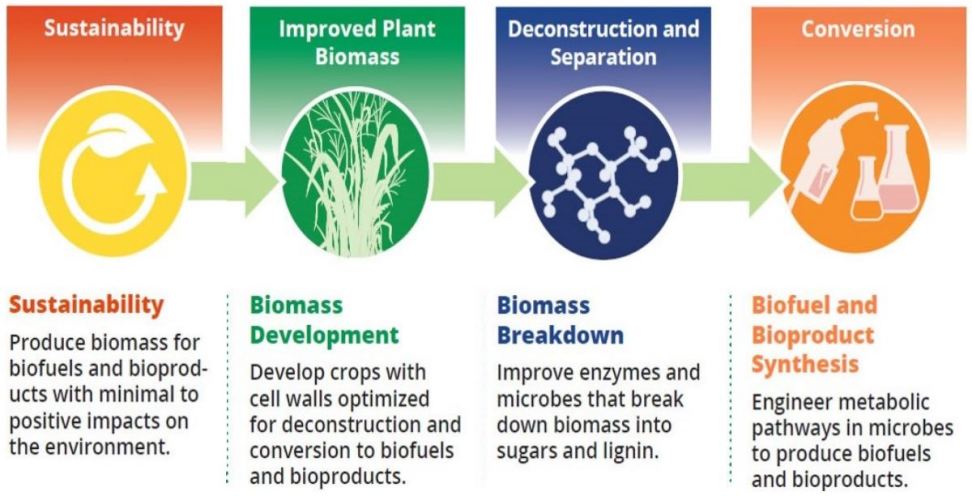

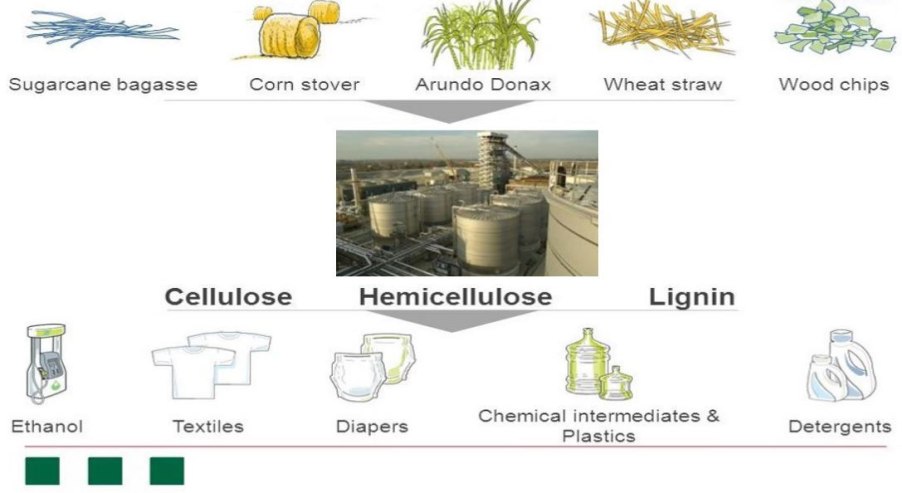

From Biomass to Advanced Biofuels and Bio-products

The Conversion of Biomass opens up to a Wide Array of Applications

Eco-friendly Biomass Film

| Ingredients |

% |

Remarks |

| Biomass PE |

< 90% |

with NB Film |

| Color contents |

6% ~ 9% |

|

| Additives |

> 1% |

|

|

| Mechanical Properties |

Unit |

NB.Film(T-die) |

B.Film(Blown) |

| Basis Weight |

|

|

gsm |

24.0 |

16 |

Tensile

Properties |

MD |

@ 25% |

gf/inch |

650 |

1400 |

| @ Peak |

900 |

1600 |

| Elongation |

% |

450 |

40 |

| CD |

@ 25% |

gf/inch |

600 |

170 |

| @ Peak |

750 |

200 |

| Elongation |

% |

500 |

300 |

| W.V.T.R |

|

g/㎡.da |

|

2300 |

| y |

| Hydrohead |

|

Hydrohead |

mbar |

60 |

|

* Test method :

- Tensile stength : Grip distance(2.0 inch), Specimen width(1.0 inch), Cross head speed(508 mm/min)

- W.V.T.R : ASTM E96 / - Hydrohead : Flow speed of water : 60 Mbar/min

Eco-friendly Biomass Film

| Item |

Contents |

Remarks |

| Bio-degradable resin |

> 70% |

|

| Color contents |

15% ~ 25% |

CaCO3 |

| Additives |

1% ~ 5% |

|

|

| Item |

Bio-degradable plastic |

Remarks |

| Grade |

Applied Bio-degradable

Certification |

|

| Raw Material |

Use biodegradable

materials as PLA/PBS |

PBAT |

| Certification Standard |

Bio-degradable resin  70% 70% |

|

| Certification Name |

Korea Eco-label (KSM 3100-1) |

|

| Certification Organization |

Korea Environmental Industry &

Technology Institute (KEITI) |

|

|

| Mechanical Properties |

Unit |

Standard

(NB Film) |

Bio-degradable

Film |

| Basis Weight |

|

|

gsm |

24 |

24 |

Tensile

Properties |

MD |

@ 25% |

gf/inch |

650 |

500 |

| @ Peak |

900 |

700 |

| Elongation |

% |

400 |

350 |

| CD |

@ 25% |

gf/inch |

550 |

400 |

| @ Peak |

750 |

550 |

| Elongation |

% |

500 |

350 |

|